Video: Simulation to understand powder flow and compaction

James Elliott, Professor of Macromolecular Materials Science at the University of Cambridge's Department of Materials Science & Metallurgy, outlines work in his group in the ADDoPT project to model, simulate and understand better powder flow and compaction behaviour in key drug product formulation operations such as compaction, and coating.

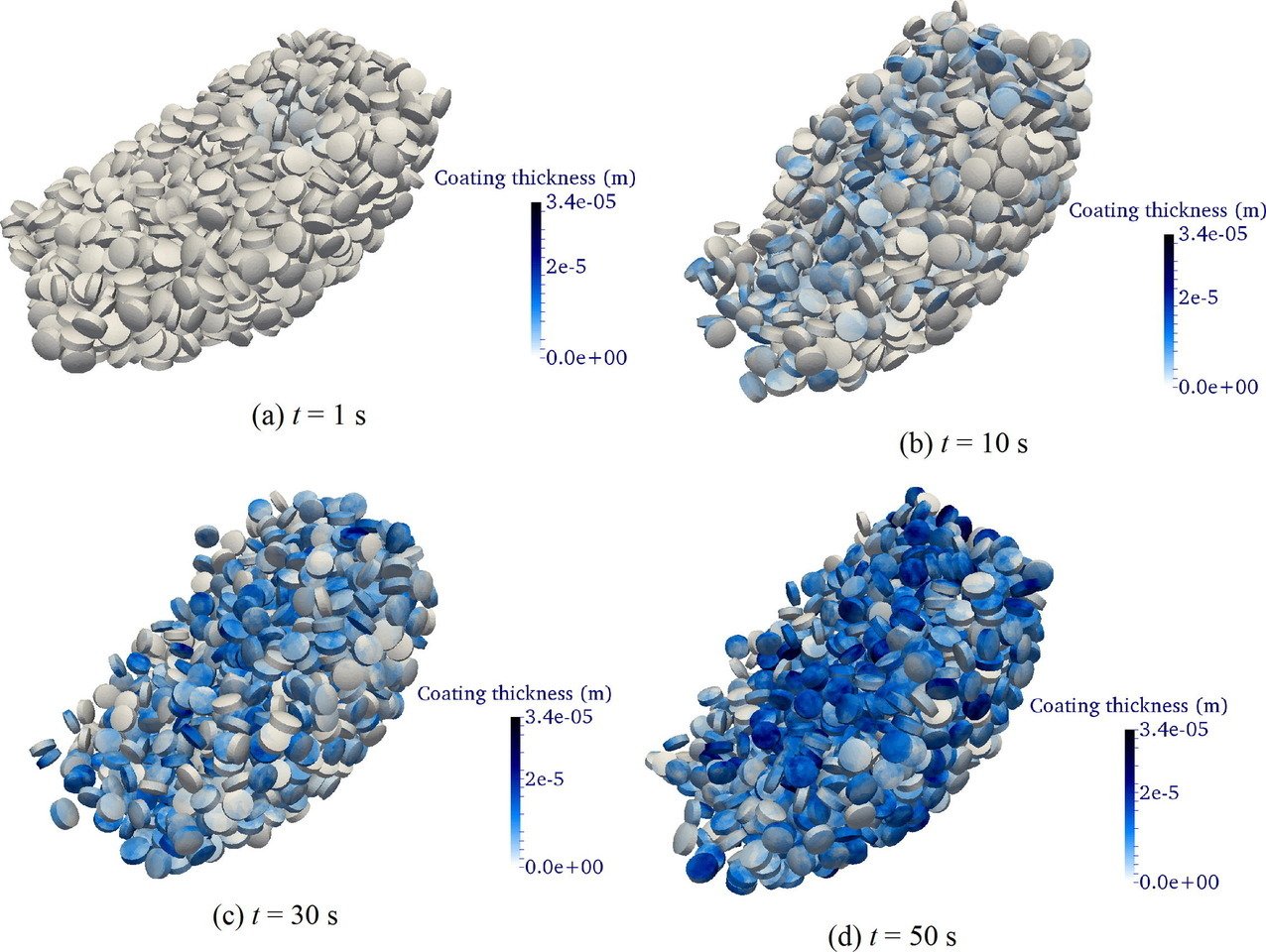

The Cambridge ADDoPT team has modelled the dynamics of tablets in a rotating pan using discrete element method (DEM) simulations and image analysis and ray-tracing sampling methods to model the spray coating process onto the tumbling tablets and analyse the cap-to-band coating thickness ratio.

The image opposite shows the progress of a coating simulation with time with the application of coating to tablet surfaces being indicated by the increasing depth of blue colour.

(Image from Pei, C., Elliott, J.A., Chemical Engineering Science, Volume 172, 23 November 2017, Pages 286-296, https://doi.org/10.1016/j.ces.2017.06.029)